ENGINEERING – INTEGRATED SOLUTIONS

ENGINEERING

«Engineering ingenuity at the highest level:

technology is our passion»

OVERVIEW

- Research / preliminary studies

- Conception of solutions in the field of drivetrain systems

- Baseline and detailed calculations

- Construction & design of components and assembly units

- Preparation of production documentation

- Documentation

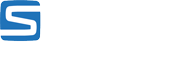

The process starts with the customer’s idea regarding a required technical solution for a drivetrain system or vehicle. Usually, a project then begins with the ascertainment and definition of the actual problem. The combination of high-tech engineering, production and testing facilities under the same roof, results in a unified approach to problems. This gives us a comprehensive understanding of all perspectives. With our many years of experience in the field of motorsports and our passion for technology, our engineers come up with creative solutions to seemingly unsolvable problems – We deliver where others have failed.

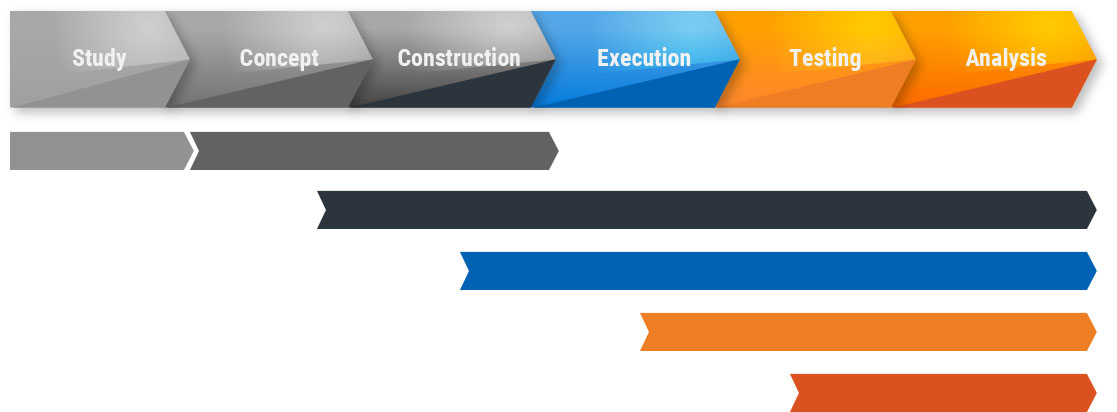

Shorten project duration with all processes under one roof:

High-tech engineering is a core competence at Suter Industries and all stages of development are made in-house. This results in smooth and fast transition phases. We minimize development time and avoid problems that can arise when outsourcing to outside firms.

PRELIMINARY STUDY

Based on the given idea or concept, problem analysis is carried out. A clear formulation of goals corresponding to the customer’s wishes as well as a cost-benefit analysis and realistic project planning are key foundations for the successful processing of an order.

CONCEPT

Guided by the findings from the preliminary study and the customer’s specifications, we develop potential solutions in close cooperation with the customer. Our aim is to always find the best possible solution. There is no challenge too big for us. At the conclusion of this phase, the customer receives a practical design concept and a clearly defined schedule.

CONSTRUCTION & DESIGN

On the basis of the design concept, components and assembly units are then developed. The necessary CFD and/or FEM calculations are performed by our experienced engineers. Our many years of expertise in engine development ensures a high degree of functional designs. Here too, the customer receives clear and precise development documentation which sets out plans for the production.

We would be pleased to provide you with an individual offer: